|

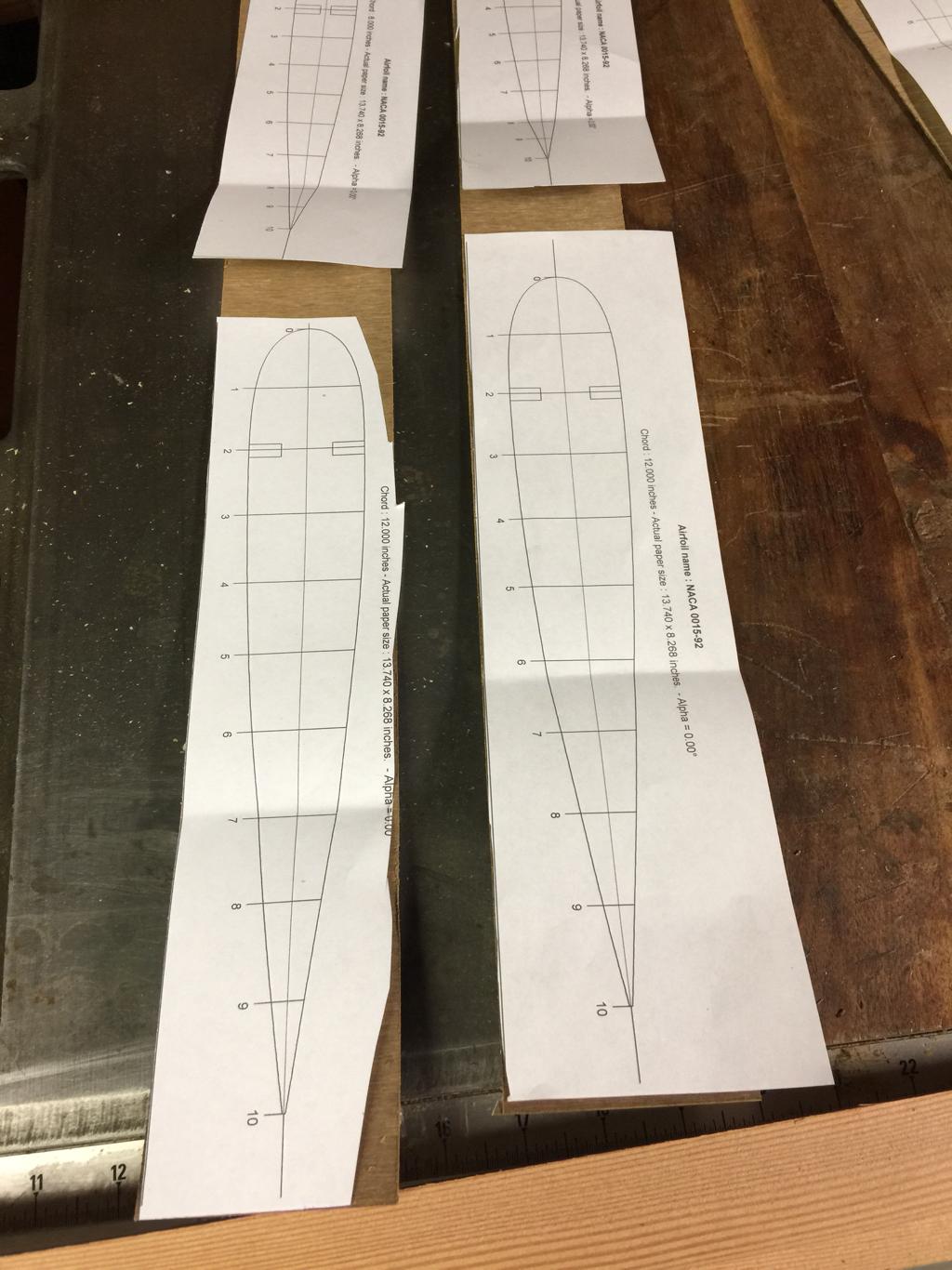

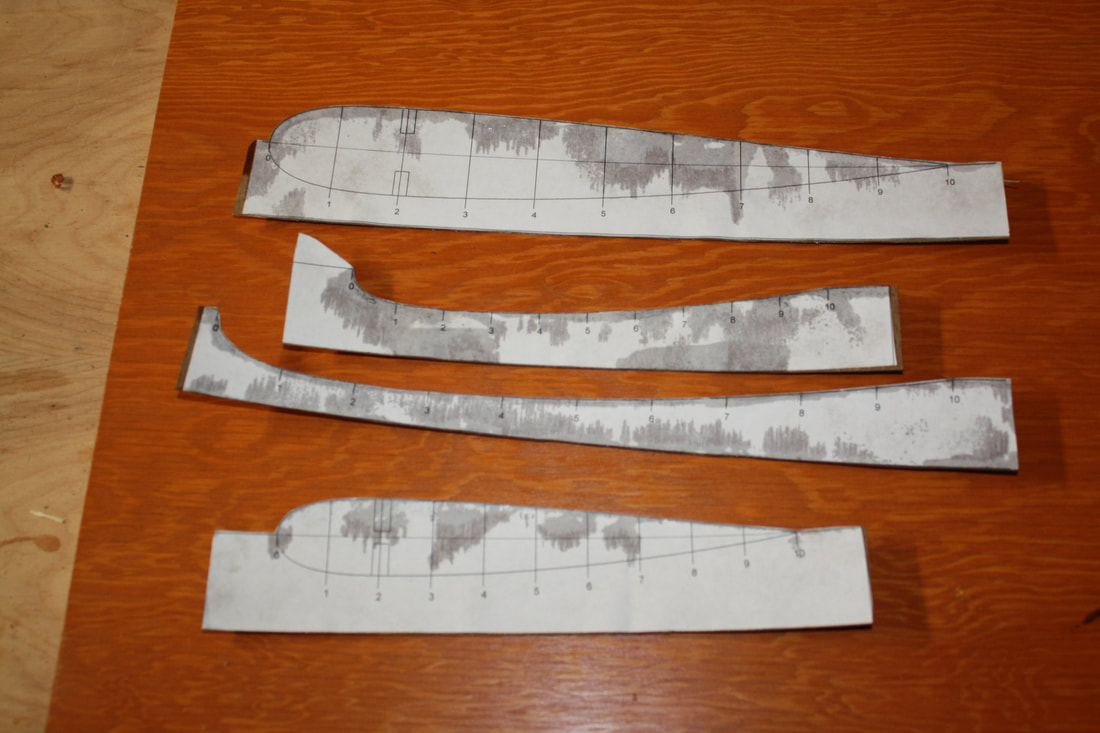

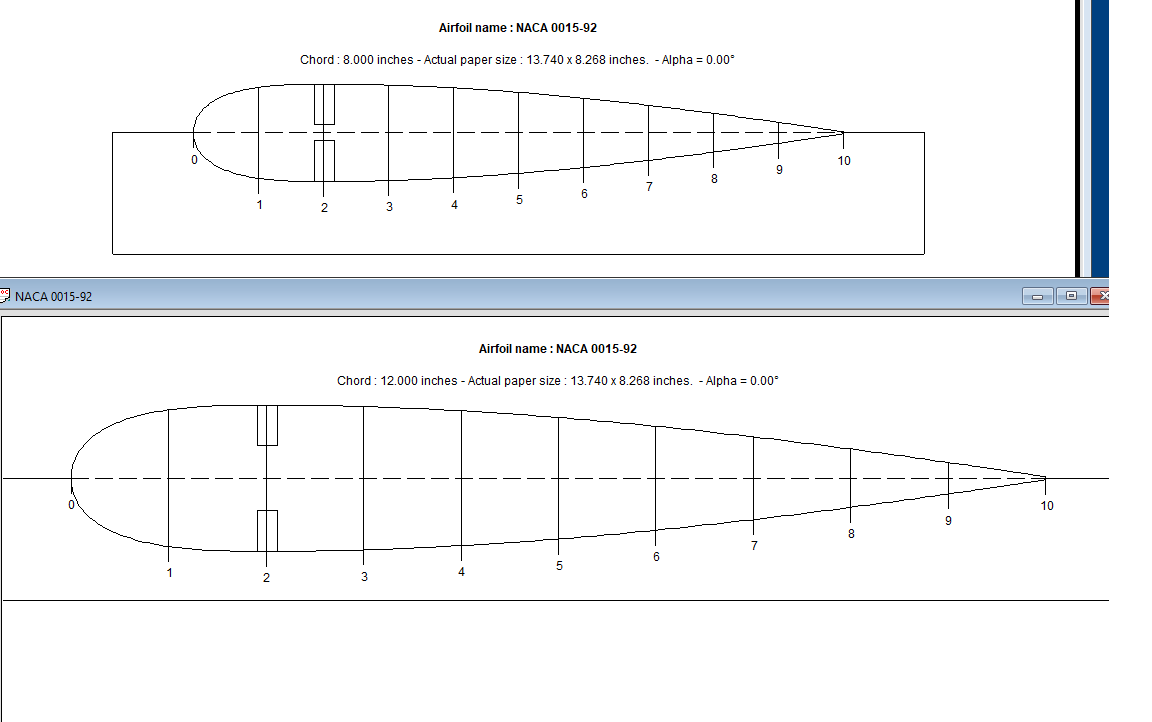

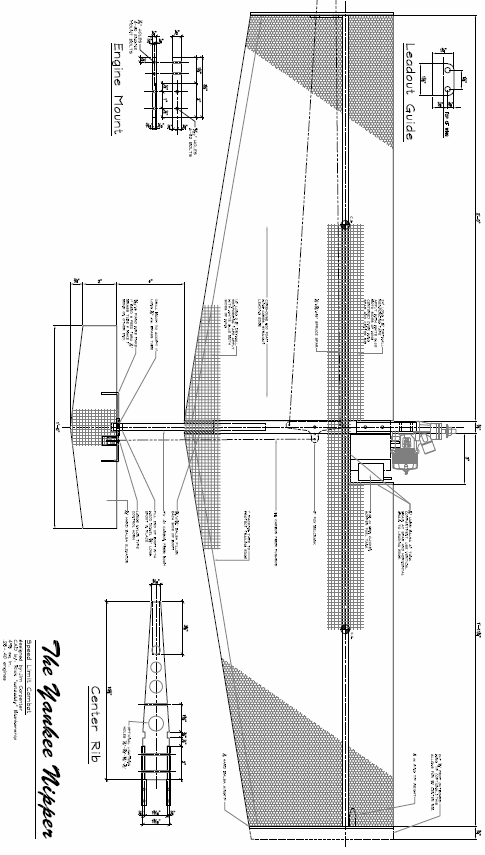

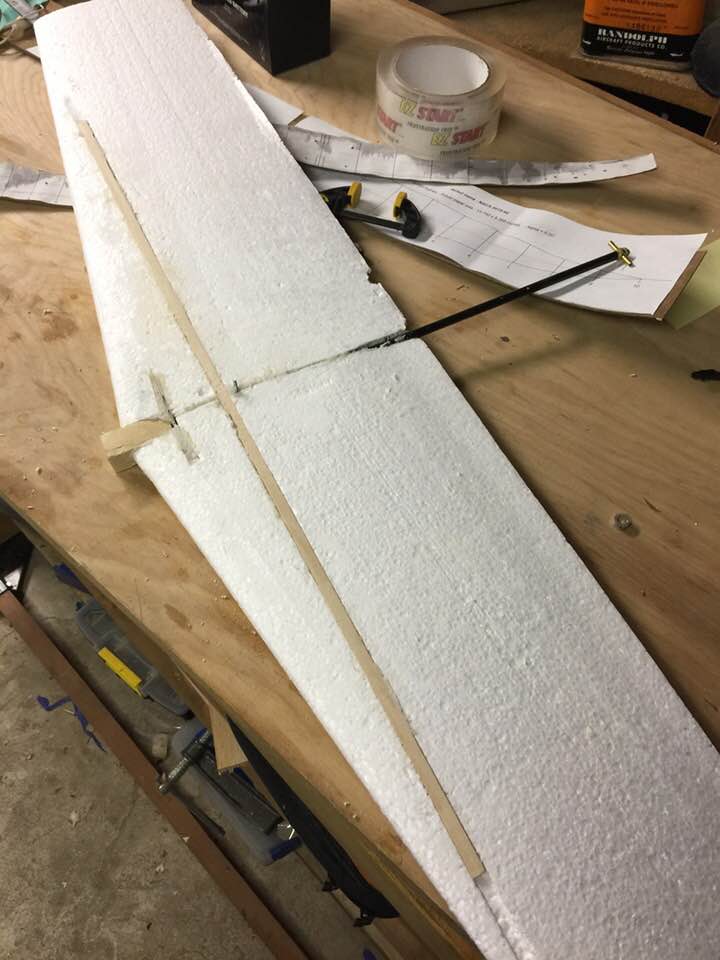

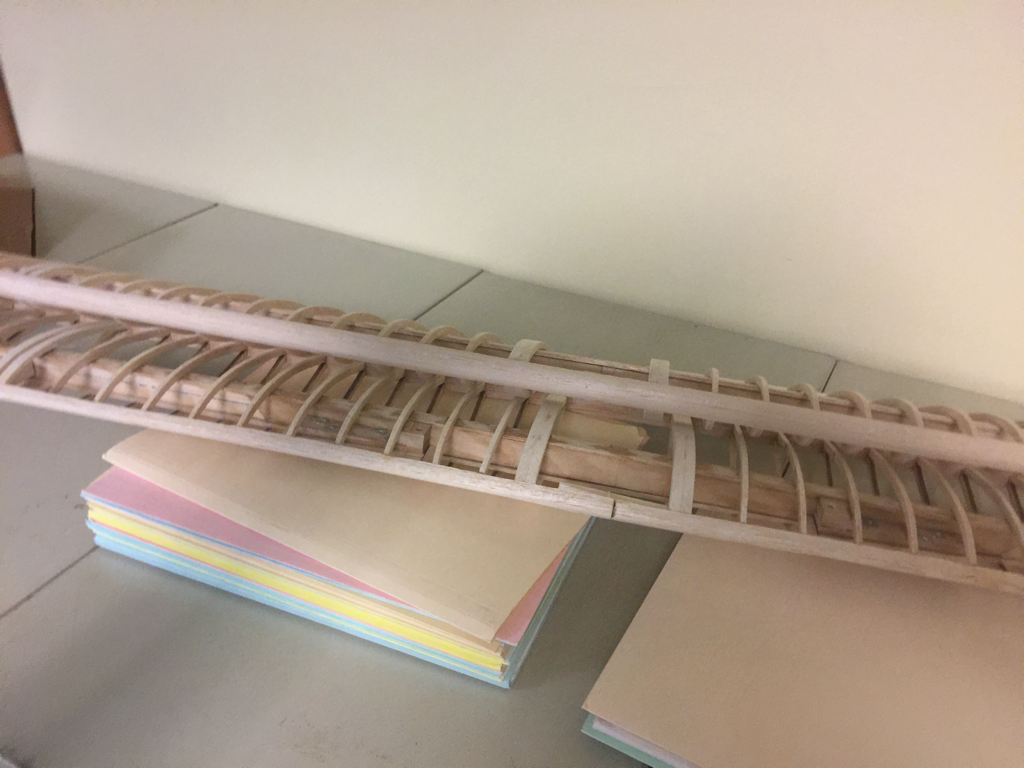

I am going to build a few foamies this winter for speed limit and general screwing around. They will be about 52 inches in span with a 12 inch root and 8 inch tip chord. The airfoil is a NACA0015-92, The -92 moves the high point forward from 30 to 20% and blunts the leading edge. It will have a tapered spars top and bottom. The spar notch it too large on the pictures. I will cut the foam on my home brew weight fall foam cutter. At least one will have a hard tank and all will allow mufflers when practice flying. It will be a lot like the Yankee nipper except a little leading edge sweep helps in a crash and I think the boom needs to be a little longer. Power will be one of my OS SFR 25's wiht metal motor mounts. templates all ready for final polishing and wing cutting Spar stock, some old growth douglass fir. cut offs from another project. beautiful grain  Not much progress, the templates did not product good cores. I need to rethink the lead in angles when using a feather cut system. While the feather cus system is really cool, many things have to be perfect to wok out. The scrap however has been turned into some more 1/2A airplanes. The cuts were made with a single template and a fixed pivot. I get very good results wiht that method.

1 Comment

Bob Furr

11/22/2017 10:34:20 am

From experience I would go with a tip airfoil that is a little thicker to avoid tip stalls in high circle turns. I have had similar wings come spinning down after a tip stall directly overhead.

Reply

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

March 2018

Categories |

RSS Feed

RSS Feed