|

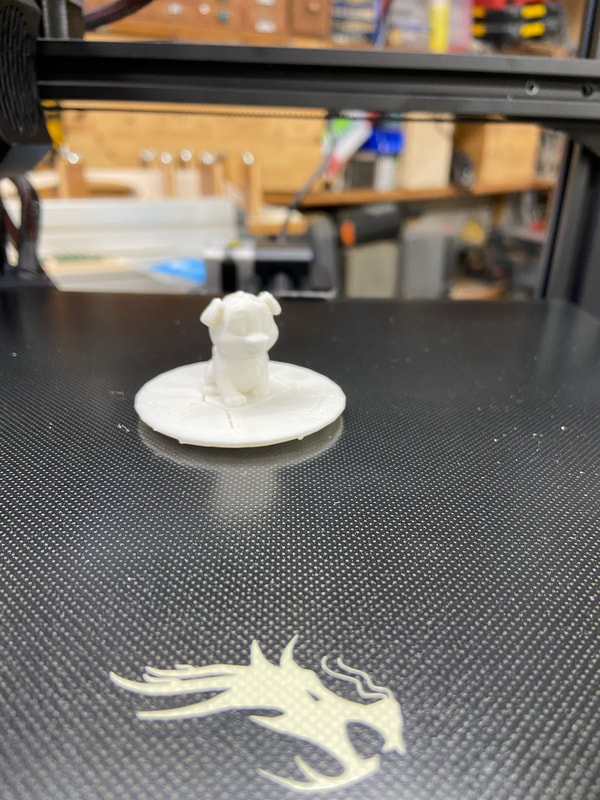

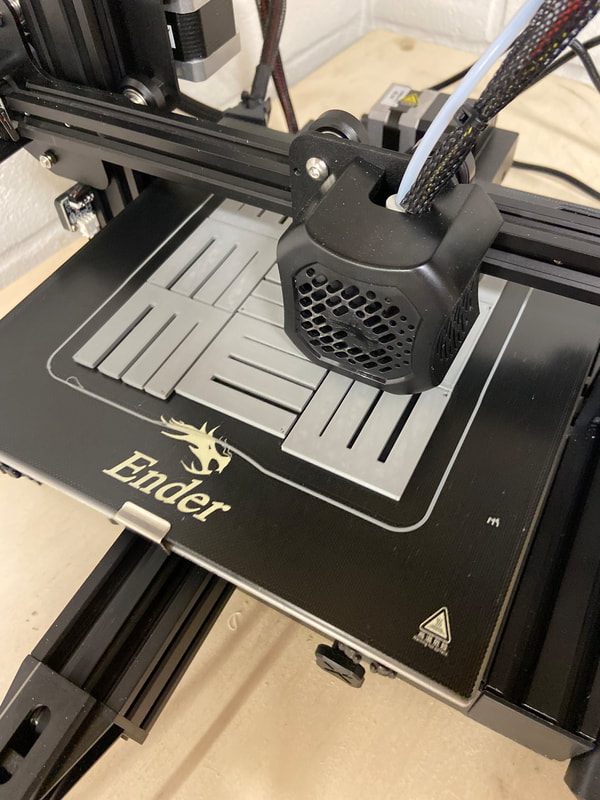

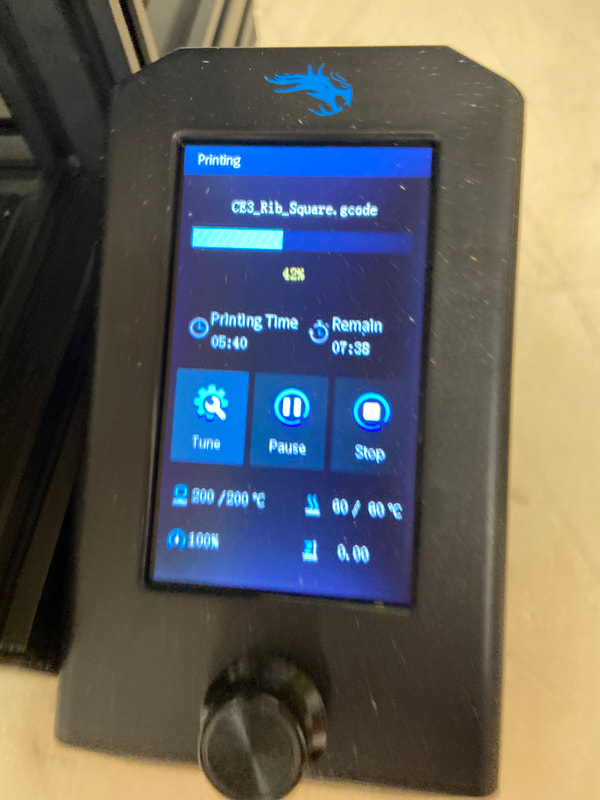

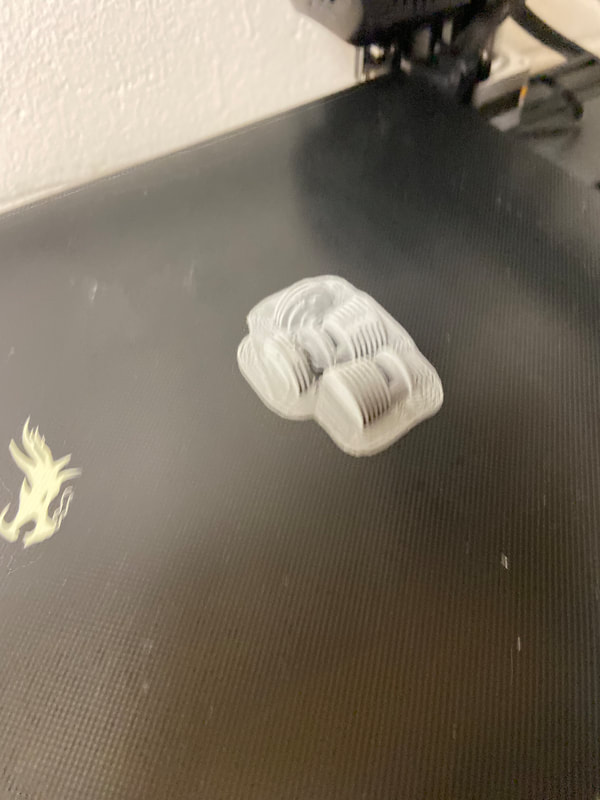

Yes I got a 3d printer for Christmas. It has been a lot of fun figuring it out. I am using it to print out stuff related to the airplane and HAM radio hobby. The printer will make enclosures for circuit boards, wheels, jigs and fixtures for building. Scale details like Dummy engines, machine guns and bombs are possible with this unit. The printer is kind of a quality entry level one, in the $200 range. It is a Creatlity Enender. Its a nice printer and has a nice low cost upgrade path, if I need to print harder material like nylon/ I did add a monitoring system that runs on a Raspberry PI single board computer. I had a Pi3 not being used, and with a spare old web cam, a few USB cables, and a download of Octopi I was all set. OctoPi is a free open source software package to monitor and control printers. It runs on Raspberry Pi, Windows and Linux computers. Where did get the designs to print? Lots of designs that people have already drawn are in on line libraries, or you can make them in a 3d drawing package like Tinker CAD or solid works. 3d files can be downloaded from yeggi . Once the drawing is done, you run a program called a slicer to lay out the layers and tool path. This generated what is called G code. G code contains the position of the print head and the tool path. G code describes each layer. The g code is sent to the printer and a print is made. Its a lot easier than this all sounds. The printer took about 3hrs to set up and print the first example files. I printed wheels, dummy cox cylinders, and building aids right away. Pretty happy with it. Here is a short 10 second video of a wheel being printed. it takes on frame every 10 seconds. So a 45 minute print is compressed to 11 seconds

0 Comments

Leave a Reply. |

Archives

January 2021

Categories |

RSS Feed

RSS Feed